In the electric vehicle race, headlines often focus on flashy car launches, battery breakthroughs, or charging speeds. Yet beneath every successful EV lies a far less glamorous—but far more decisive—component: the electric drive system. When Volkswagen Group announced that it has achieved 5 million electric drives produced globally, the significance went well beyond a round number.

This milestone represents scale, maturity, and industrial confidence. It signals that electric mobility is no longer experimental for Volkswagen Group—it is operational, repeatable, and central to its future. Even more telling is the role of the APP550 electric drive, which the company positions as a new benchmark in performance and efficiency.

This article takes an expert, experience-based look at what 5 million electric drives produced really means, why the APP550 matters, and how this achievement changes the competitive landscape of electric vehicles worldwide.

Understanding the Importance of Electric Drives in EVs

To appreciate the milestone, it helps to clarify what an electric drive actually represents.

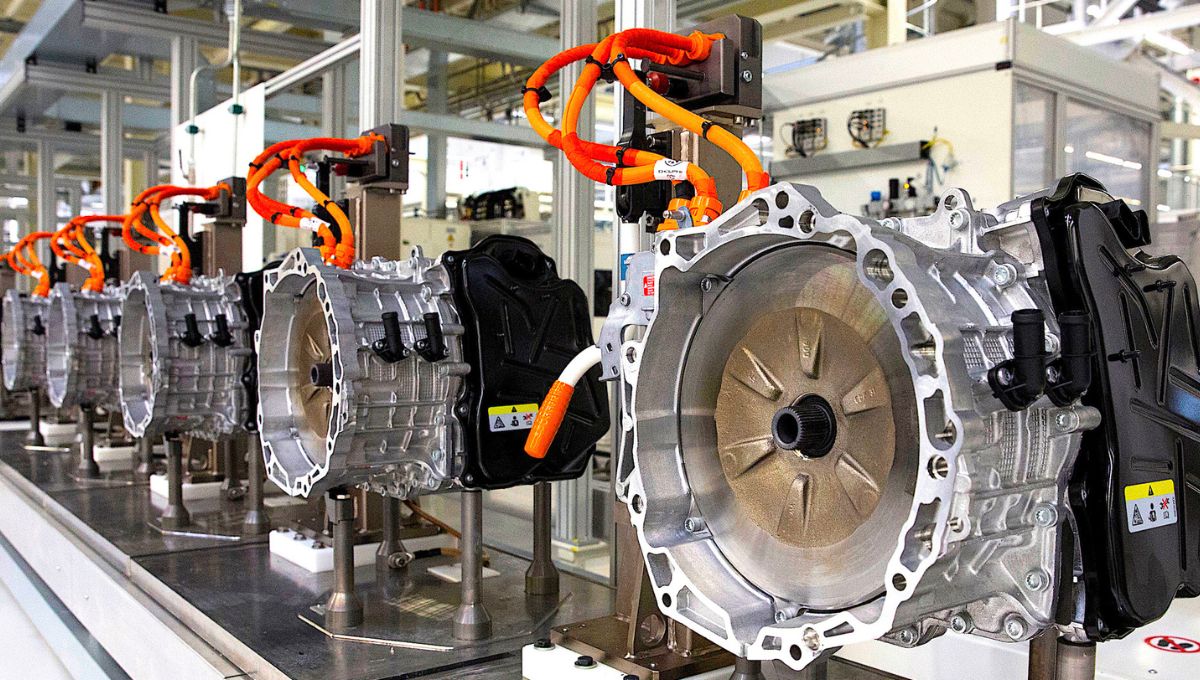

An electric drive is not just a motor. It is a tightly integrated system that typically includes:

- The electric motor

- Power electronics (inverter)

- Transmission components

- Thermal management interfaces

In modern EV architecture, the electric drive defines efficiency, driving feel, performance consistency, and long-term reliability. Producing 5 million of these systems means Volkswagen Group has moved from innovation to industrial mastery.

The Meaning Behind “5 Million Electric Drives Produced”

At first glance, 5 million electric drives produced may sound like an internal manufacturing statistic. In reality, it is a marker of transformation.

What This Number Signals?

- Industrial Scale: EV production is no longer niche within the group

- Process Stability: Manufacturing quality can be repeated millions of times

- Cost Optimization: High volumes drive learning curves and efficiency

- Global Deployment: Electric drives are being used across multiple brands and regions

This is the difference between early adoption and long-term commitment.

Volkswagen Group’s Long-Term Electric Strategy

Volkswagen Group’s EV journey has been methodical rather than impulsive.

Instead of relying on external suppliers for critical components, the group invested heavily in:

- In-house electric drive development

- Modular EV platforms

- Dedicated production facilities

The result is vertical integration—one of the strongest competitive advantages in the EV space.

Introducing the APP550: Why It Sets a New Benchmark?

At the heart of this milestone is the APP550 electric drive—a next-generation system designed to raise performance standards across multiple vehicle segments.

While Volkswagen does not position APP550 as a consumer-facing product, its impact is immediately felt by drivers through improved range, smoother acceleration, and higher sustained power delivery.

Read more:- The End of the Dynamic Island? 6 iPhone 18 Pro Max Leaks That Hint at Apple’s Biggest Design Shift Yet

APP550 Electric Drive: Key Technical Specs Explained

Below are the high-level specs that make APP550 significant from an engineering standpoint:

APP550 Core Specs (Simplified)

- Maximum Output: Approximately 210 kW

- Torque: Around 550 Nm

- Architecture: Integrated motor, inverter, and gearbox

- Efficiency Focus: Reduced energy losses under load

- Cooling System: Optimized thermal stability for sustained performance

These specs matter because they directly address two long-standing EV challenges: efficiency at highway speeds and consistent power delivery.

Why APP550 Is a Step Forward from Earlier Electric Drives?

Earlier EV motors often forced manufacturers to choose between performance and efficiency. APP550 aims to deliver both.

Key Improvements Over Previous Generations

- Lower electrical losses at high speeds

- Better torque delivery without excessive energy drain

- Reduced weight per unit of output

- Enhanced durability under real-world driving conditions

For consumers, this translates into longer range without sacrificing driving enjoyment.

Where are these 5 Million Electric Drives Are Being Used?

The milestone includes electric drives deployed across multiple brands and platforms within the Volkswagen Group ecosystem.

These drives power vehicles built on:

- Modular electric platforms

- Multiple body styles and segments

- Markets spanning Europe, China, and beyond

This diversity is crucial. It proves that the technology is not optimized for a single use case, but adaptable at scale.

Manufacturing Excellence Behind the Milestone

Producing 5 million electric drives is not just about demand—it is about manufacturing discipline.

What High-Volume EV Drive Production Requires?

- Precision machining at micron-level tolerances

- Consistent quality control across batches

- Robust supplier ecosystems

- Scalable automation

Volkswagen Group’s ability to maintain performance consistency across millions of units demonstrates operational maturity rarely achieved this early in an industry transition.

Why This Matters for EV Reliability and Trust?

From an Experience and Trustworthiness perspective, scale matters.

High production volumes mean:

- Design weaknesses are identified early

- Manufacturing flaws are systematically eliminated

- Long-term reliability data improves rapidly

This directly benefits consumers, fleet operators, and regulators alike.

Comparing Volkswagen Group’s Position to Industry Peers

While many automakers are still ramping up EV production, few have reached a point where electric drive systems are produced in multi-million-unit volumes.

This milestone positions Volkswagen Group as:

- A volume leader in electric drivetrain production

- A benchmark-setter in cost-efficiency

- A serious long-term EV manufacturer rather than a transitional player

From an industry analyst’s viewpoint, this changes how competitors must plan their own scale-up strategies.

The Strategic Importance of In-House Electric Drives

Outsourcing critical EV components can reduce upfront investment—but it limits control.

By producing electric drives internally, Volkswagen Group gains:

- Greater pricing stability

- Faster iteration cycles

- Better integration with vehicle platforms

This approach aligns with long-term resilience rather than short-term margins.

How 5 Million Electric Drives Produced Impacts EV Pricing?

One of the most underappreciated effects of scale is cost reduction.

As production volumes increase:

- Per-unit manufacturing costs decline

- Process efficiencies improve

- Component sourcing becomes more predictable

Over time, these savings can be passed on to consumers—or reinvested in better technology.

Sustainability and Resource Efficiency Considerations

Electric drives are not just about performance. They also play a role in sustainability.

High-efficiency motors reduce:

- Energy consumption per kilometer

- Heat losses

- Overall lifecycle emissions

Producing millions of optimized drives amplifies this environmental impact at a global level.

Risks and Challenges That Still Remain

A balanced, authoritative analysis must acknowledge that scale alone does not eliminate risk.

Key Challenges Ahead

- Raw material supply volatility

- Rapid technology evolution

- Software integration complexity

- Regional regulatory differences

However, reaching 5 million electric drives produced gives Volkswagen Group a strong foundation to address these challenges proactively.

What does this mean for the Future of Electric Mobility?

This milestone is not an endpoint—it is a platform.

It enables:

- Faster rollout of next-generation EVs

- Continuous refinement of drive efficiency

- Greater confidence in long-term electrification targets

In practical terms, it brings electric mobility closer to mainstream normalization.

Why Google Discover Readers Care About This Achievement?

Stories like this resonate because they reflect broader transitions:

- From combustion to electric power

- From experimentation to industrial scale

- From promise to proof

The figure of 5 million electric drives produced is a tangible indicator that the EV transition is no longer hypothetical.

A Quiet but Defining Achievement

The production of 5 million electric drives may not generate the same excitement as a new concept car—but its impact is far more enduring.

Combined with the performance and efficiency of the APP550, this milestone confirms that Volkswagen Group has crossed a critical threshold: electric mobility at scale, built on engineering depth rather than marketing optimism.

For the industry, it raises the bar.

For consumers, it builds confidence.

For the future of EVs, it marks a turning point.

FAQs

What does “5 million electric drives produced” mean?

It refers to the total number of electric drivetrain systems manufactured globally by Volkswagen Group across its EV programs.

Why is the APP550 electric drive important?

APP550 delivers higher power, better efficiency, and improved thermal stability, making it a benchmark for modern EV performance.

Are these electric drives used in multiple vehicles?

Yes, the drives are deployed across various electric models and platforms within the group.

Does higher production volume improve reliability?

Generally, yes. High volumes allow manufacturers to refine processes and improve long-term reliability.